NC membrane

The membrane is considered the most critical element in LFA strips and nitrocellulose is by far the most commonly used material.

- Product Details

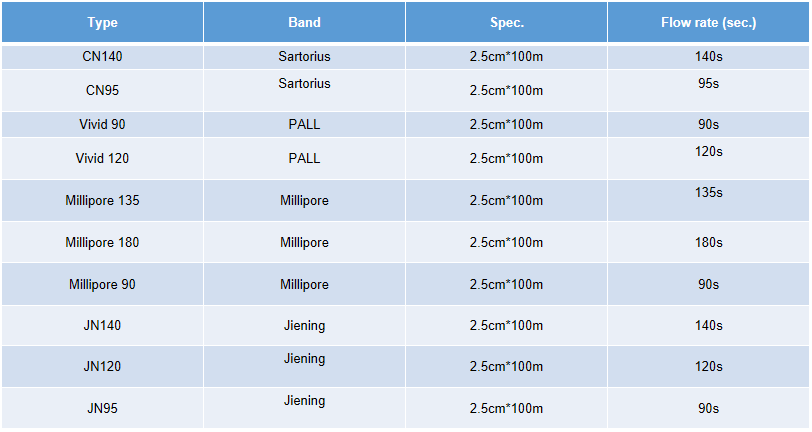

- Technical Specification

The membrane is considered the most critical element in LFA strips and nitrocellulose is by far the most commonly used material. Moreover, there are also ‘pillar-based’ capillary LFA devices used for deoxyribonucleic acid(DNA) hybridization detection (where micropillar arrays replace the membrane), which have the advantage of more precise control of the capillary flow. Important parameters characterizing a good membrane material are the capillary forces, as well as the ease of binding and immobilizing proteins necessary for subsequent selection, reaction and detection. A range of nitrocellulose pore sizes are available, from 0.05 to 12 μm. However, as the pores are not equally distributed (because of the manufacturing process), capillary flow time is a more accurate parameter and it should be used when selecting the most effective strip material. The capillary flow time is the time required for the liquid to travel to and completely fill the strip of the membrane.

-NC membrane is a polymer.

-The function of NC membrane is to fix specific target molecules through their adsorption characteristics in the test and control line, while the simple and test conjugate are guided to the reaction area. To achieve this goal, the membrane must have a uniform high protein adsorption capacity and a certain amount of porosity and wettability to ensure capillary flow of aqueous samples. The properties of many polymer porous membranes can meet some or all of the requirements.

-The nitrocellulose membrane is a critical component that contains the test and control line reagents and provies the readout of the results to the end user. During development, it is important to select the correct membrane type and optimize the striping parameters of your test and control line reagents to achieve the desired results.

RELATIVE FLOW TIME | RELATIVE PORE SIZE | RELATIVE SENSITIVITY | EXAMPLES |

FAST | LARGE | LOW | Millipore:HF 75,90 Sartorius:CN 95 MDI:NC 15 μm Whatman/GE: AE 98, AE99 |

MEDIUM | MEDIUM | MEDIUM | Millipore:HF 120,135 Sartorius:CN 140, CN 150 MDI:NC 8 μm Whatman/GE: FF120HP |

SLOW | SMALL | HIGH | Millipore:HF 180 MDI:NC 5 μm Whatman/GE: FF170HP |

MATERIAL AND TYPE

Nitrocellulose membranes are available in various grades and porosities that wick an applied liquid sample at different speeds. Many manufacturers label their various grades based on the capillary flow time, which is the amount of time (seconds) required for the solvent front to advance 4 cm.

In a fast nitrocellulose such as Millipore HF75, the solvent front progresses by 4 cm in 75 seconds.

In a slow nitrocellulose, such as Millipore HF180, it takes 180 seconds (2.4 times longer) to cover the same distance. Some manufacturers may also label their grades in pore size (um), which is directly related to the capillary flow time. A larger pore size correlates with a faster membrane (lower capillary flow time), and a smaller pore size correlates with a slower membrane (higher capillary flow time). Using a slower membrane (smaller pore size/higher capillary flow time) will increase the assay time. Slow speeds increase the incubation time between the nanoparticles, the analyte, and the test line, which in turn can increase the sensitivity. Faster membranes (larger pore size/lower capillary flow time), reduce the incubation time between the reagents in the system and yields a faster result (Table 3). Viscous samples (e.g. saliva, undiluted plasma, or solubilized solids) run more slowly than non-viscous samples such as urine and may flow better using faster.

Reel to reel dispenser DS3000

Reel to reel dispenser DS3000  Dispenser sprayerXYZ3020

Dispenser sprayerXYZ3020  Assembly rollerAR3000

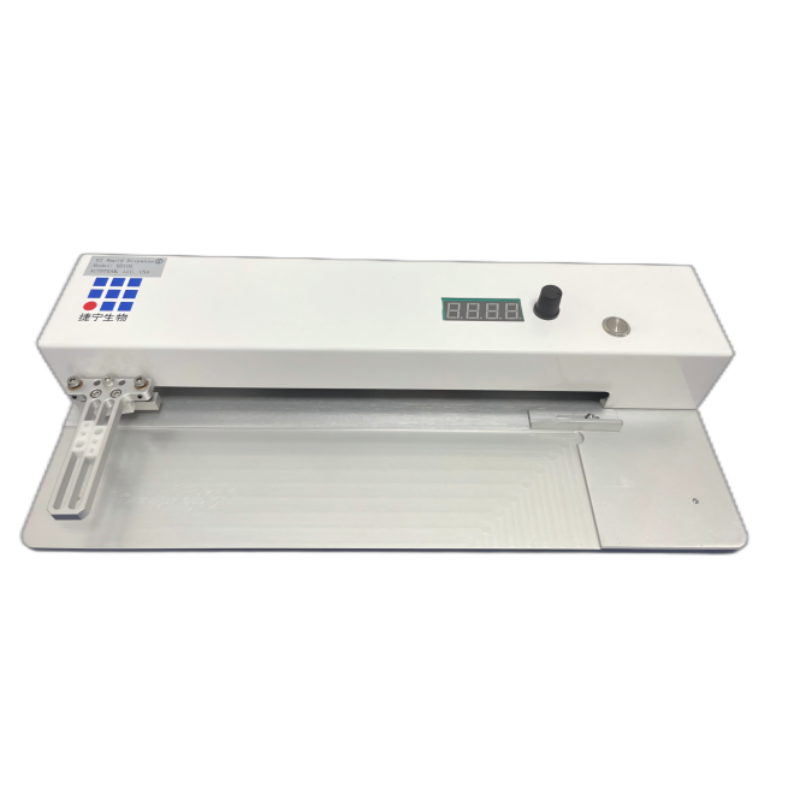

Assembly rollerAR3000  Guillotine cutter CM3020

Guillotine cutter CM3020  Simple Dispenser 100 (SD100)

Simple Dispenser 100 (SD100)  Sample Pad Buffer

Sample Pad Buffer  NC membrane

NC membrane  Glass fiber

Glass fiber  Plastic backing

Plastic backing  Polyester membrane

Polyester membrane