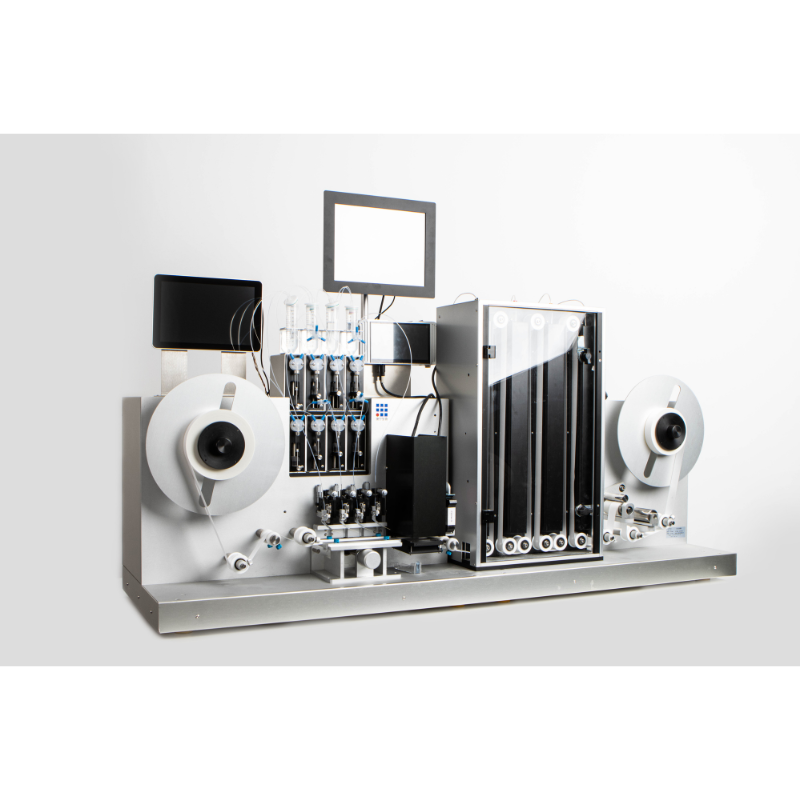

Reel to reel dispenser DS3000

Model:DS3000

Application:Used for reagent stripping on NC membrane in mass production of colloidal gold and fluorescent products

Fast dispensing speed, High efficiency, Drying module saves space and time, Necessary equipment for mass production

The reel to reel dispenser is the flagship model newly launched by Jiening Company in 2024. It is designed to coat and dry antibody on roll-shaped NC membranes. This instrument integrates membrane coating and drying into one system, with precise temperature control for drying. It replaces the traditional drying process in large-scale production, reducing manufacturing steps and improving production efficiency.

Platform compatibility: Suitable for lateral flow chromatography colloidal gold and fluorescence platforms.

It supports customization of evaluation samples based on customer formulations and provides on-site trial support to customers.

The number of coating lines can be expanded according to customer requirements (up to 4 lines).

Recommended usage scenario: Large-scale production.

Integrated in one assembly line to realize production automation and scale / High level of quality and process control

-Material requirement: Width 5-30mm and outer diameter of the coil ≤300mm

-Configuration:2 Lines(cTline) and maximum 4 lines

-Spacing:0mm-25mm stepless adjustable, minimum spacng 1mm

-Dispensing volume: 0.1-10ul/cm

-Speed:10-100 mm/s

-Y&Z axises of dispensing tip can be adjusted independently: +0.1mm

-Dring module temperature: room temperature to 70℃,Temperature accuracy: 1°C

-Equipment size: Length 1500*width 600*Height 700mm

-After stripping the defect position wil be automaticaly marked by CcD vision inspection system.

-Drying or pre-drying in the dryer then rewinding

-Vision system (optional) adopts CCD inspection and japanese KEYENCE smart camera with a high precision and good accuracy.

-Tecan injection pump --precise and durable, removable accessaries, low cost of accessories replacement and cost-effective.

-Equipment operation control system uses a computer to automaticaly record the parametersin the producion process and it is easy to trace with the producion log file.

-Backward suction convenient for sample test before production: Solution recycle,save reagents

Reel to reel dispenser DS3000

Reel to reel dispenser DS3000  Dispenser sprayerXYZ3020

Dispenser sprayerXYZ3020  Assembly rollerAR3000

Assembly rollerAR3000  Guillotine cutter CM3020

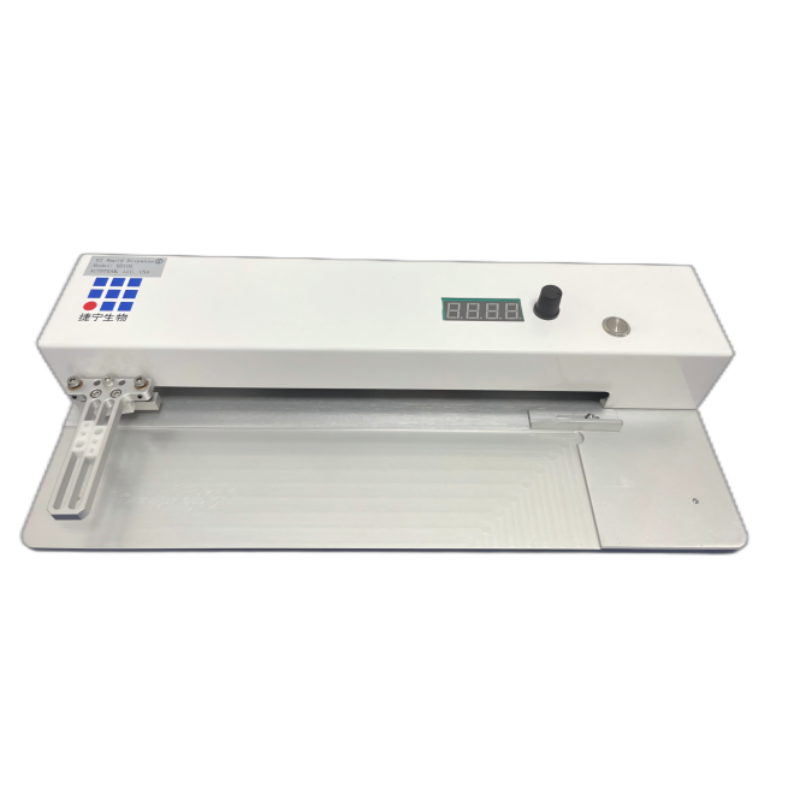

Guillotine cutter CM3020  Simple Dispenser 100 (SD100)

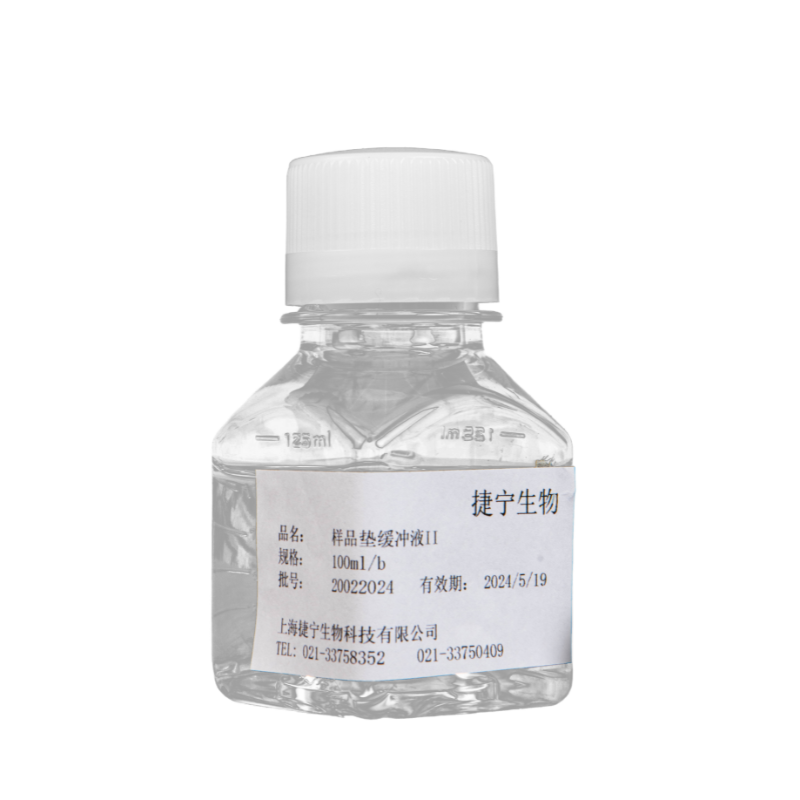

Simple Dispenser 100 (SD100)  Sample Pad Buffer

Sample Pad Buffer  NC membrane

NC membrane  Glass fiber

Glass fiber  Plastic backing

Plastic backing  Polyester membrane

Polyester membrane