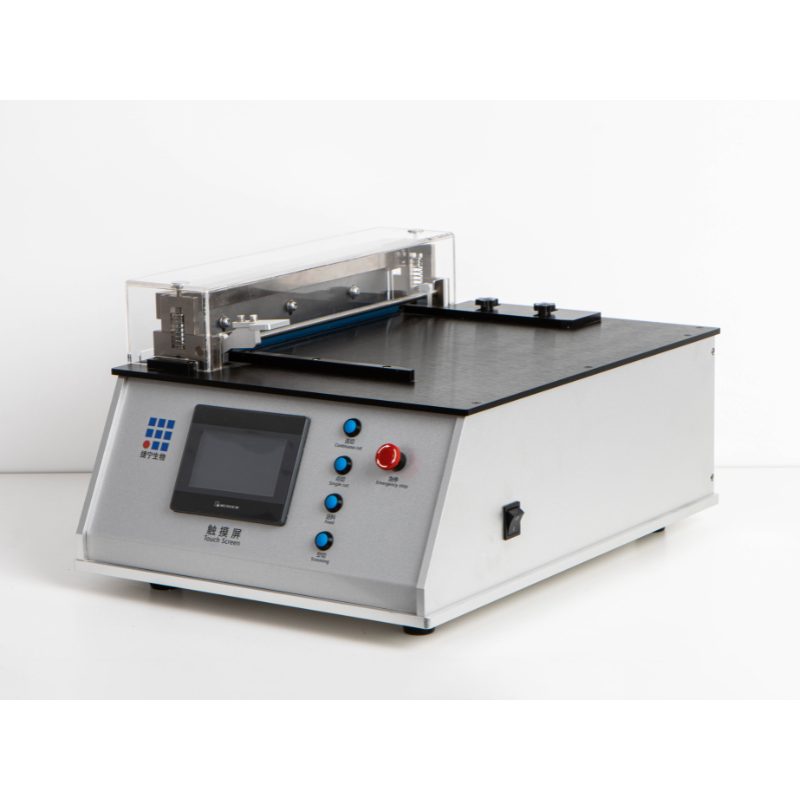

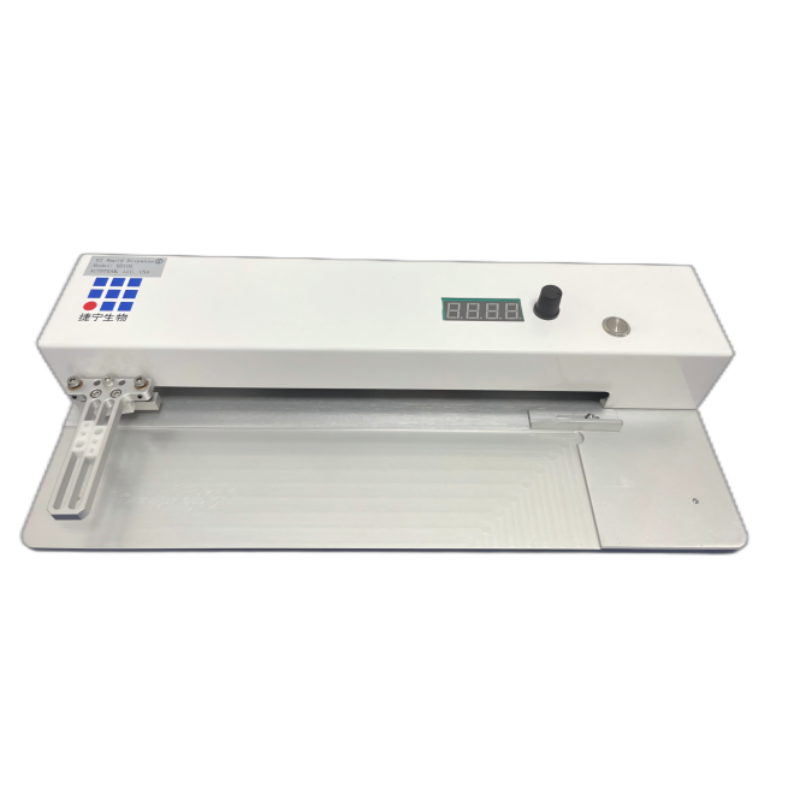

Test Accessories Cutter

Model:FL3100

Application:Customized for R&D and production

- Product Details

- Technical Specification

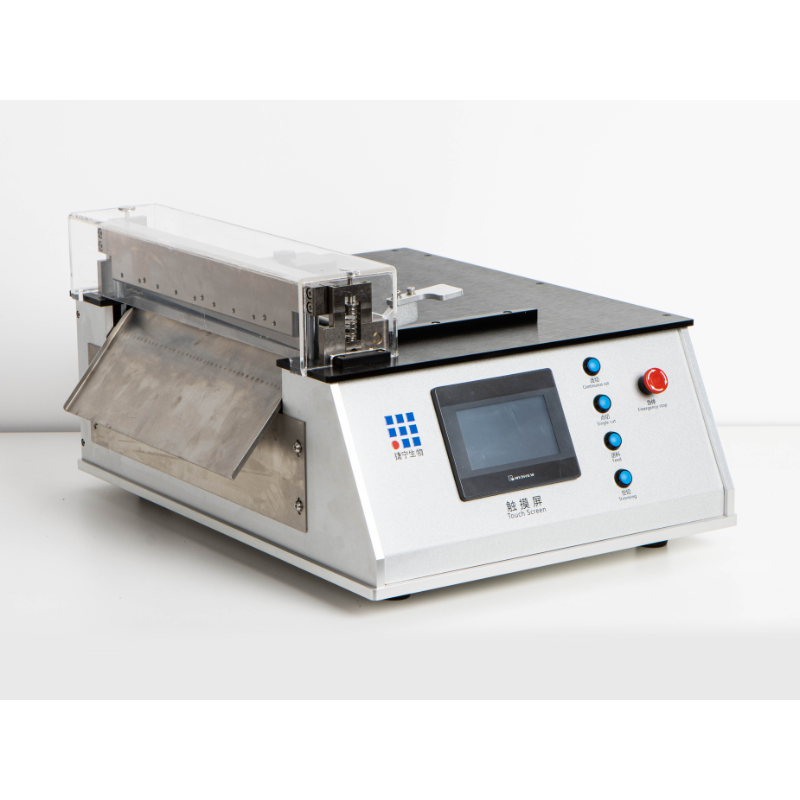

The equipment is user-friendly and easy to maintain.

It operates smoothly and has high production efficiency.

The maintenance procedures are simple and quick, minimizing downtime to the maximum extent.

Automatically controlled by computer chip, easy to operate, direct cutting width&speed settings.

- Uniquely designed adjustable limit guide to easily keep the materials of different widths in a fixed place.

- Elastic roller feeding design with auto feeding function and can protect the materials better.

- The wear-resistant high-carbon steel blade has a zero-gap structure to effectively solve the rough edge,ensure the strip quality, extend the life of blade and reduce noise.

- Operate directly on control panel for continuous or single strip cuttings to meet a variety of work needs.

- Counting system records the number of cutting strips in a single work cycle or totally.

- Specially designed red "emergency stop" safety button can make the machine stop working immediately.

- Used and verified by many strip manufacturers for many year's continuous and stable production.

Technical Parameter

-Material width: <310mm

-Feeding length: Unlimited.Cutting width: 2-200mm

-Cutting width setting digits: 0.01 mm.Cutting accuracy:+0.15mm

-Cutting speed: 400 times/min.Power:220VAC 50HZ/60HZ

-Weight: 30KG

-Size:500(L)x600(W)x470(H)mm

Payment & After-sales

-Payment term: 100% before delivery

-Delivery time: To the designated locationwithin one week after signing the contract

-After-sales:Manufacturer sends professionalengineers for on-site installation, trial run andtraining before the buyer accepts it.

-Fast andtimely after-sale response.

-Warranty:one year

-Invoice: 13% VAT invoice after acceptancePrice validity:one month

Reel to reel dispenser DS3000

Reel to reel dispenser DS3000  Dispenser sprayerXYZ3020

Dispenser sprayerXYZ3020  Assembly rollerAR3000

Assembly rollerAR3000  Guillotine cutter CM3020

Guillotine cutter CM3020  Simple Dispenser 100 (SD100)

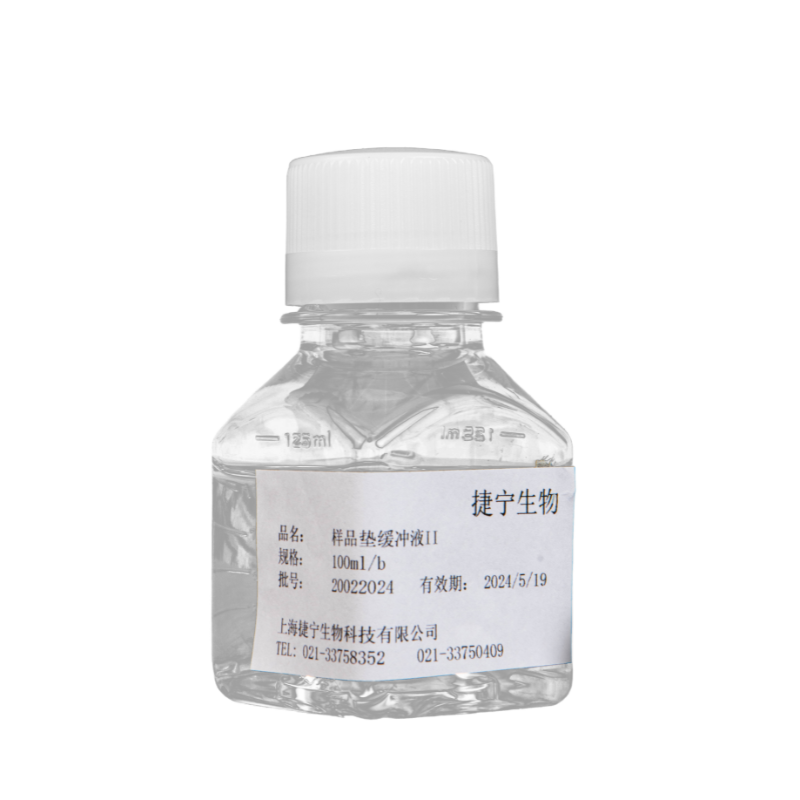

Simple Dispenser 100 (SD100)  Sample Pad Buffer

Sample Pad Buffer  NC membrane

NC membrane  Glass fiber

Glass fiber  Plastic backing

Plastic backing  Polyester membrane

Polyester membrane