Cassette Selection and Specifications

Date: 2025-01-17 Categories: Industry News Hits: 1053

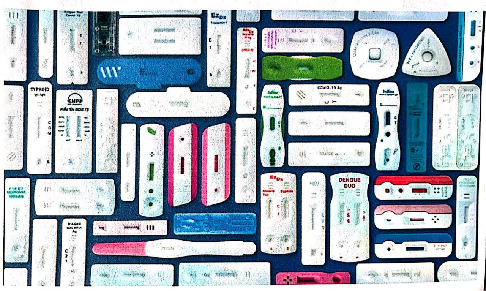

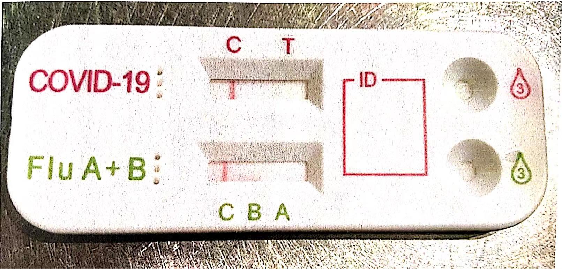

Although not required, many lateral flow strips are placed into plastic cassettes. The cassette prevents the user from applying the sample anywhere except the sample pad through the sample port. In over-the-counter products for urine analysis, the cassette also serves to protect the strip from inadvertent splash onto the membrane. External labeling on the cassette can be used to indicate the position of test and control lines and provide other information.

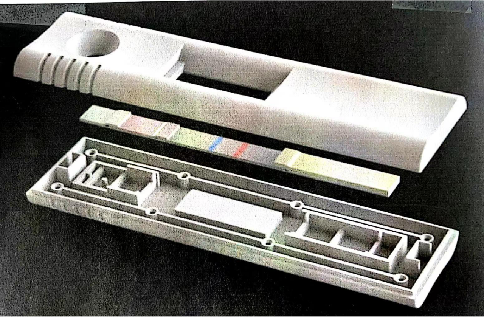

Cassettes can be obtained as off-the-shelf products or custom-designed to fit around the strip. Deciding between these options requires balancing unit cost, mold design costs, size compatibility with the strip, and requirements for external labeling. Ultimately, the dimensions and tolerances on the internal features need to be matched to the dimensions and tolerances of the materials that comprise the test strip. Internal pins and bars are used to hold the strip in place relative to the sample port and viewing window. They hold the materials in intimate contact with one another while the test strip is running. If these features are too large, the pads and membrane may be compressed to the point that sample flow is blocked. The plastic used for the housing must also be biocompatible.In recent years, the availability of 3-D printing has made it possible to design and test cassette prototypes in a cost-effective and rapid manner. Key design features can be evaluated and specified prior to committing to the expense of having molds created.

The cost of mold development can be significant and includes testing and validation to ensure that all parts manufactured from the mold meet specification. If the mold needs to be retooled or completely redesigned, the additional cost must be factored into the product development budget.

The cassette that houses the test strip can be one of the most critical components to achieve a reproducible and reliable assay, which is especially important for quantitative tests. The cassette provides optimal flow control by applying pressure at appropriate points on the strip to ensure that all the fluid passes through the strip assembly at the same flow rate. It also needs to ensure that the fluid flows through the test strip materials rather than flooding the strip or flowing along the edges.

Typically, cassettes are designed after all materials have been selected and optimized and is customized to the lengths, widths, and thicknesses of each component. Control over the pressure can control the flow rate of the sample fluid, allowing for longer or shorter incubation times of conjugate with sample analyte. For large scale production, a custom designed cassette from an experienced industrial design company is necessary, preferably a company who already has lateral flow cassette expertise. When using a custom design, it is always important to keep in mind the mitigation of manufacturing risk down stream. This is an often overlooked, but critical component of the designing process. For initial testing, existing generic cassettes may be sufficient.

For some assays, a quantitative read-out is not required and a dipstick format may be sufficient in running the strip. In this format, the strip is not placed inside a plastic cassette. Cover tape may be used to provide some flow control and to hold all of the components of the strip together.

Reel to reel dispenser DS3000

Reel to reel dispenser DS3000  Dispenser sprayerXYZ3020

Dispenser sprayerXYZ3020  Assembly rollerAR3000

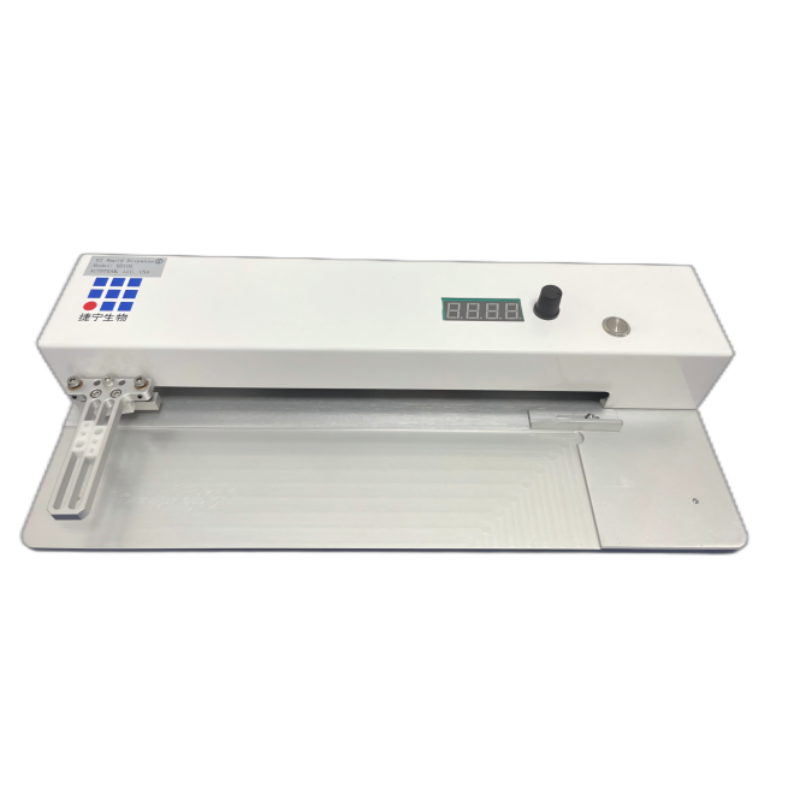

Assembly rollerAR3000  Guillotine cutter CM3020

Guillotine cutter CM3020  Simple Dispenser 100 (SD100)

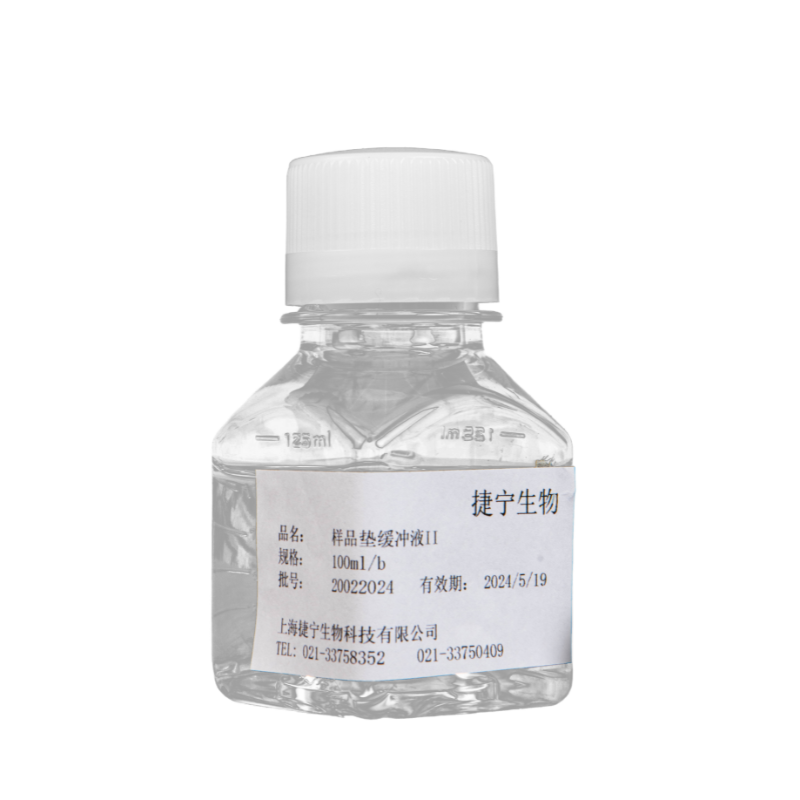

Simple Dispenser 100 (SD100)  Sample Pad Buffer

Sample Pad Buffer  NC membrane

NC membrane  Glass fiber

Glass fiber  Plastic backing

Plastic backing  Polyester membrane

Polyester membrane